Problem Statement

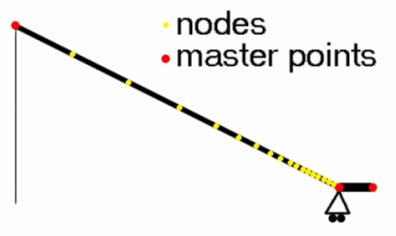

Axisymmetric modelling of conical roofs is deceptively simple! One must define only one half of the diagram shown. It requires only 3 master points, one at the cone tip, one at the edge, and one on the outside of the ring. All that then remains is to divide the model into suitably sized elements, this will most likely involve a very coarse resolution near the tip of the cone (where not much interesting is expected to happen, due to lower stresses) and a higher resolution near the supports to capture the buckling behaviour. An exact node-element used will be found in our Results and Analysis section once this is completed.

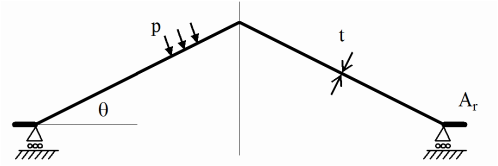

Current design standards and recommendations for the design of conical roofs have some limitations which leave the designer unsure of their applicability. Chief among these is unrealistic boundary conditions. If the designer opts to make simple boundary condition assumptions he must choose to either use a roller condition, and be knowingly conservative, while not knowing the extent to which he is being conservative, or choose a pinned boundary condition, and know his model is erring on the dangerous side.

Uncertainty in the designers mind will prompt them to use a design with which they are more familiar. In the case of conical roof shells this means rafters and purlins. The designer treats the roof as a frame structure because it allows him to think in 1D, along member axes.

An analogous thought process hardly ever occurs when it comes to simpler and better understood shell structures, most notably cylinders. Cylinder membrane behaviour is commonly incorporated into design.

Herein lies the economic justification for this research: to save on material and construction related costs by allowing the designer to use simpler designs, which ironically have more complex behaviour, and hence modelling and "understanding" costs. It is hoped that this research will make more efficient roof-forms simpler to understand and design, thus, making them cheaper.

Image from http://www.steel-silos.com/Projects-of-Steel-Storage-Silo.html

An analogous thought process hardly ever occurs when it comes to simpler and better understood shell structures, most notably cylinders. Cylinder membrane behaviour is commonly incorporated into design.

Herein lies the economic justification for this research: to save on material and construction related costs by allowing the designer to use simpler designs, which ironically have more complex behaviour, and hence modelling and "understanding" costs. It is hoped that this research will make more efficient roof-forms simpler to understand and design, thus, making them cheaper.

Image from http://www.steel-silos.com/Projects-of-Steel-Storage-Silo.html